SMC molding press is used for compression moulding of SMC BMC GMT and other composites material.

Read More...

Hydraulic SMC press is used for compression moulding of SMC BMC GMT and other composites material.

Read More...

Four Column Hydraulic Press Machine also called Four Pillar press or 4 post press,it can be used for forming the kevlar helmet and other carbon fiber material as well as composites material.

Read More...

Hydraulic Forging Press is applied in forging aluminium alloy wheel hub,magnesium alloy wheel hub and other metal forging.

Read More...

Hydraulic Forging Press is applied in forging aluminium alloy parts,magnesium alloy parts and other metal forging.

Read More...

GMT Forming Hydraulic Press is used for compression moulding of SMC BMC GMT and other composites material.If we have your basic requirements, like worktable size, stroke and max. daylight etc, we can provied you with accurate quotation.

Read More...

Warmly welcome to visit Taitian at Booth No. Hall 1 B435. China Comosites Expo is one of exhibitions that Taitian do always attend every year. China Composites Expo is the largest and most influential...

Item No.:

TT-LM1000T/LSPayment:

T/T,L/CProduct Origin:

ChinaColor:

As per customer's requirementShipping Port:

Qingdao Port,Lianyungang PortMin Order:

1 setLead Time:

About 4-5 monthsTAITIAN automotive metal stamping press also called metal forming press,hydraulic deep drawing press, it is used for deep drawing,stamping,punch of metal sheet for automobile kitchenware and household appliance industries.Taitian deep drawing press adopts Taiwan technology,the speed and pressure has been well adjutable by using servo driven control system.

Main Specification

We are able to custom manufacture hydraulic metal stamping presses in a wide range of sizes and capacities as per customers’requirement. Production line included 1000T 800T 600T, below basic data is only for reference.

Part No.

TT-LM1000T/LS

Nominal Pressure

Tons

1000

Lifting Pressure

Tons

40

Max.Stroke of

Slide

mm

1800

Max.Daylight

mm

2400

Working Table

L-R

mm

3500

F-B

mm

2500

Slide Speed

Fast Approach

mm/s

500

Pressing

mm/s

10-1

Fast Return

mm/s

400

Approx.Total

Power

KW

160

Approx.Overal

Dimension

mm

7160×7000×9100

Main Features:

1) The Hydraulic Metalforming press is available up to 3000 Ton capacity as per customer's individual specifications and requirements. Each press is designed through Finite Element Structural Analysis and optimization to assure high strength and rigidity. High capacity press is preferred in H Frame structure.

2) The metalforming press is equipped with advanced and systemized Taiwan hydraulic system featuring oil leakage resistance, anti-vibration, low energy consumption, low noise level and easy maintenance.

3) 4 sides of brass guide rails of full stroke length not only ensure high accuracy but also allow easy adjustment of slide leveling.

4) The press fully meets CE safety requirements. Two side locking cylinders lock the slide when it reaches top position. And two sets of light curtain sensors are fitted in the front and rear that will stop the machine when human body carelessly enters the working area.

5) Mitsubishi PLC and 7 / 10 inch Taiwan Weinview touch screen make the machine easy for operation and specification adjustable.

6) Each press is manufactured under strict quality control management with good quality components from France, Japan, Germany, USA and Taiwan to assure the best performance and accuracy. H Frame deep drawing press has been awarded with CE Certificate.

Optional:

1. Moving Bolster / Die Change Trolley

2. T-slots on slide or bolster

3. Stamping Dampers for shock proof while stamping

4. Ejectors on slide or bolster

Applications:

Deep draw press is applied in production techniques, like deep drawing, stamping, cutting, bending, flanging of metal sheet.

Particularly applied in the following industries:

1) Automobile Industry: battery cover, vehicle body, chasis, axle housing, fuel tank, door, wheelbarrow tray and more.

2) Household Appliance Industry: Components for air conditioner, refrigerator, washing machine, microwave oven, electric cooker etc.

3) Kitchen Ware Industry: Stainless steel utensil, LPG cylinder, cooking bench, Aluminum Cookware.

Hydraulic Control System

Hydraulic control system takes high precision logic valving system as standard. Pipeline configuration is simple and clear, making maintenance easy. Pipeline connection way preferentially adopts flange joint to avoid oil leakage.

All motors, pumps and pipes are fitted based on advanced Taiwan technology to achieve shock-resistance.

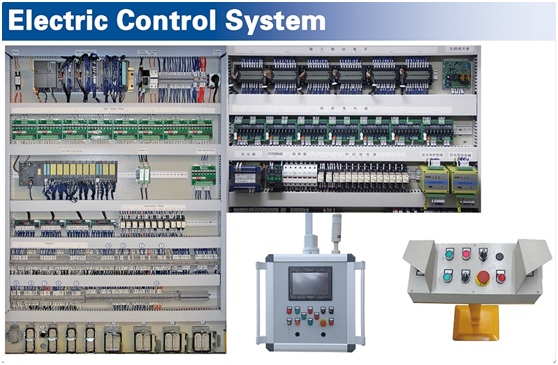

Electric Control System

Electric box is featured with dustproof, waterproof and oil proof. Adopt Schneider electric units to ensure high quality. All units to ensure high quality. All units have labels, so it's clear to identify and easy to maintain.

Production Process:

Certification:

1000T Hydraulic Deep Drawing Press/Metal Stamping Press

1000T Hydraulic Deep Drawing Press/Metal Stamping Press

Hydraulic Deep Drawing Press is applied in deep drawing,stamping,punch of metal sheet for automobile, kitchenware and household appliance industries.

2400T Hydraulic Metal Forming Press for New energy vehicle battery case

2400T Hydraulic Metal Forming Press for New energy vehicle battery case

Hydraulic Metal Forming Press is applied in metalforming ,deep drawing,stamping,punch of automobile battery cover,metal sheet for automobile, kitchenware.

1000T Kitchen Utensils Deep Drawing Press Machine

1000T Kitchen Utensils Deep Drawing Press Machine

Hydraulic Deep Drawing Press Machine is applied in metalforming ,deep drawing kitchen utensil wheelbarrow tray.

1200T High-strength Steel Hot Stamping Press Machine

1200T High-strength Steel Hot Stamping Press Machine

1200T automotive high-strength steel hot stamping machine, full stroke 1400mm, using servo proportional valve and special filling valve, high response servo pump control system, optimized piping system.

1000T Hydraulic SMC Moulding Press Machine with CE Standard

1000T Hydraulic SMC Moulding Press Machine with CE Standard

Hydraulic SMC Moulding Press Machine is applied in compression moulding of comosites materials like SMC,BMC,FRP,GRP and so on.

5000T Hydraulic Composites Forming Press

5000T Hydraulic Composites Forming Press

This equipment is specially used for compression molding of thermosetting/thermoplastic composite materials, including SMC, BMC, DMC, GMT, LFT-D, LFT-G and other materials; such materials are widely used in ships, automobiles, building materials, electric power Electrical appliances, electronic communications, rail transit, home improvement and bathroom, animal husbandry, aerospace and other fields.

1500T Hydraulic Die Spotting Press/Die Tryout Press machine

1500T Hydraulic Die Spotting Press/Die Tryout Press machine

Hydraulic Die Spotting Press also called Die Tryout Press, it is used for the spotting of dies, mold finishing and die inspection. They can be used for a wide range of different industries, such as mould factory, automotive and aerospace industry.

200 Tons Hydraulic Press for Automobile Interior Trim Parts

200 Tons Hydraulic Press for Automobile Interior Trim Parts

Automobile Interior Parts hydraulic molding press is specially designed for automobile interior trim parts. It is applied in hot forming and shearing of auto interior trim parts.

C Frame High-speed Hydraulic Press Machine

C Frame High-speed Hydraulic Press Machine

C Frame High-speed Hydraulic Press Machine also called Hydraulic Punching Press Machine, it is used for stamping,punching,forming and assembling of auto parts,and metal hardware parts.

The professional team to service !