SMC molding press is used for compression moulding of SMC BMC GMT and other composites material.

Read More...

Hydraulic SMC press is used for compression moulding of SMC BMC GMT and other composites material.

Read More...

Four Column Hydraulic Press Machine also called Four Pillar press or 4 post press,it can be used for forming the kevlar helmet and other carbon fiber material as well as composites material.

Read More...

Hydraulic Forging Press is applied in forging aluminium alloy wheel hub,magnesium alloy wheel hub and other metal forging.

Read More...

Hydraulic Forging Press is applied in forging aluminium alloy parts,magnesium alloy parts and other metal forging.

Read More...

GMT Forming Hydraulic Press is used for compression moulding of SMC BMC GMT and other composites material.If we have your basic requirements, like worktable size, stroke and max. daylight etc, we can provied you with accurate quotation.

Read More...

Warmly welcome to visit Taitian at Booth No. Hall 1 B435. China Comosites Expo is one of exhibitions that Taitian do always attend every year. China Composites Expo is the largest and most influential...

Hydraulic Forging Press is applied in forging aluminium alloy parts,magnesium alloy parts and other metal forging.

Item No.:

TT-LM500TPayment:

T/T,L/CProduct Origin:

ChinaColor:

As per customer's requirementShipping Port:

Qingdao,ShanghaiMin Order:

1 setLead Time:

About 4 months

TAITIAN offers Hydraulic Cold Forging Press, included hydraulic cold forging press and hydraulic hot forging press that use localized compressive forces to shape metal into very rigid objects. It is used for forging aluminium alloy parts,magnesium alloy parts and bicycle components and other small metal parts. The capacity of Taitian cold / hot forging press can be up to 16000tons , adopts Taiwan technology, the speed and pressure has been well adjustable by using servo driven control system.

Main Specification:

We are able to custom manufacture hydraulic cold forging press machine/hot forging presses in a wide range of sizes and capacities as per customers’ requirement.

|

Part No. |

TT-LM500T |

||

|

Nominal Pressure |

Tons |

500 |

|

|

Lifting Pressure |

Tons |

17 |

|

|

Max.Stroke of Slide |

mm |

600 |

|

|

Max.Daylight |

mm |

800 |

|

|

Working Table |

L-R |

mm |

1200 |

|

F-B |

mm |

1000 |

|

|

Slide Speed |

Fast Approach |

mm/s |

350 |

|

Pressing |

mm/s |

10-1 |

|

|

Fast Return |

mm/s |

300 |

|

|

Approx.Total Power |

KW |

55 |

|

|

Approx.Overal Dimension |

mm |

3842×2800×5117

|

|

Characteristics:

1) The hydraulic Cold Forging press machine is designed through finite element structural analysis and optimization to assure high strength and rigidity.

2) The advanced design of one main cylinder and two lifting cylinders fully ensures a good balance.

3) Integrated cartridge valve is introduced for flexible and reliable movement without oil leakage.

4) Siemens PLC and Schneider electric components provide the press with stable performance.

5) Hydraulically safety loop and locking device on the top dead center (T. D. C. ) assure high safety.

Optional:

Applications:

Cold /Hot Forging Press is suitable for forging parts of aluminum alloy, copper, titanium alloy and magnesium alloy needed in hand tools, autos, sports equipments, medical equipments etc.

Hydraulic Control System

Hydraulic control system takes high precision logic valving system as standard. Pipeline configuration is simple and clear, making maintenance easy. Pipeline connection way preferentially adopts flange joint to avoid oil leakage.

All motors, pumps and pipes are fitted based on advanced Taiwan technology to achieve shock-resistance.

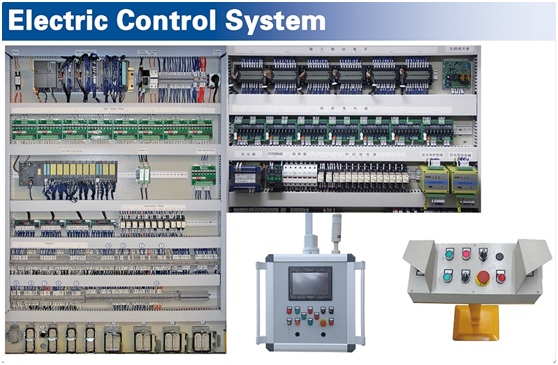

Electric Control System

Electric box is featured with dustproof, waterproof and oil proof. Adopt Schneider electric units to ensure high quality. All units to ensure high quality. All units have labels, so it's clear to identify and easy to maintain.

10000T Hydraulic Forging Press for Wheel Hub

10000T Hydraulic Forging Press for Wheel Hub

Hydraulic Forging Press is applied in forging aluminium alloy wheel hub,magnesium alloy wheel hub and other metal forging.

10000T Hydraulic Forging Press for Wheel Hub

10000T Hydraulic Forging Press for Wheel Hub

Hydraulic Forging Press is applied in forging aluminium alloy wheel hub,magnesium alloy wheel hub and other metal forging.

5000T Hydraulic Composites Forming Press

5000T Hydraulic Composites Forming Press

This equipment is specially used for compression molding of thermosetting/thermoplastic composite materials, including SMC, BMC, DMC, GMT, LFT-D, LFT-G and other materials; such materials are widely used in ships, automobiles, building materials, electric power Electrical appliances, electronic communications, rail transit, home improvement and bathroom, animal husbandry, aerospace and other fields.

10000T Hydraulic Forging Press for Wheel Hub

10000T Hydraulic Forging Press for Wheel Hub

Hydraulic Forging Press is applied in forging aluminium alloy wheel hub,magnesium alloy wheel hub and other metal forging.

2400T Hydraulic Metal Forming Press for New energy vehicle battery case

2400T Hydraulic Metal Forming Press for New energy vehicle battery case

Hydraulic Metal Forming Press is applied in metalforming ,deep drawing,stamping,punch of automobile battery cover,metal sheet for automobile, kitchenware.

2000T Hydraulic Press Machine for Forming SMC Door

2000T Hydraulic Press Machine for Forming SMC Door

SMC Door Forming Press is used for compression moulding of SMC Door Skin and other BMC FRP,GRP,GMT composites material.

Carbon Fiber Forming Press/Hot Forming Press Machine

Carbon Fiber Forming Press/Hot Forming Press Machine

Carbon fiber forming press also called carbon fiber hot forming press,it can be used for blow moulding forming carbon fiber 3C exterior trimming parts and sports parts.

Hydraulic Forming Press for SMC/GRP/FRP/GMT Molding

Hydraulic Forming Press for SMC/GRP/FRP/GMT Molding

SMC molding press is used for compression moulding of SMC BMC GMT and other composites material.

800T Hydraulic Die Tryout Press Machine with Lower Movable Bolster

800T Hydraulic Die Tryout Press Machine with Lower Movable Bolster

Hydraulic Die Tryout Press also called Die Spotting Press, mould tryout press, it is used for the spotting of dies, mold finishing and die inspection. They can be used for a wide range of different industries, such as mould factory, automotive and aerospace industry.

The professional team to service !