SMC molding press is used for compression moulding of SMC BMC GMT and other composites material.

Read More...

Hydraulic SMC press is used for compression moulding of SMC BMC GMT and other composites material.

Read More...

Four Column Hydraulic Press Machine also called Four Pillar press or 4 post press,it can be used for forming the kevlar helmet and other carbon fiber material as well as composites material.

Read More...

Hydraulic Forging Press is applied in forging aluminium alloy wheel hub,magnesium alloy wheel hub and other metal forging.

Read More...

Hydraulic Forging Press is applied in forging aluminium alloy parts,magnesium alloy parts and other metal forging.

Read More...

GMT Forming Hydraulic Press is used for compression moulding of SMC BMC GMT and other composites material.If we have your basic requirements, like worktable size, stroke and max. daylight etc, we can provied you with accurate quotation.

Read More...

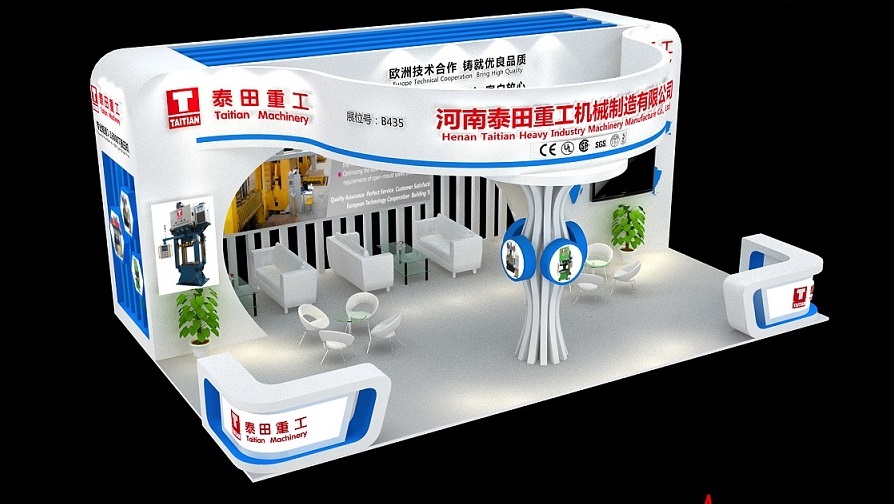

Warmly welcome to visit Taitian at Booth No. Hall 1 B435. China Comosites Expo is one of exhibitions that Taitian do always attend every year. China Composites Expo is the largest and most influential...

Item No.:

TT-LM800T;TT-LM1200TPayment:

T/T,L/CProduct Origin:

ChinaColor:

As per customer's requirementShipping Port:

Qingdao,ShanghaiMin Order:

1 setLead Time:

4-5 months

Scope of application:

This SMC hydraulic press is used for GRP water tank panel, it can be also used is for other compression molding of thermosetting/thermoplastic materials, including BMC, DMC, GMT, LFT-D, LFT-G and other materials; this type of material is widely used in ships, automobiles, building materials, power appliances , Electronic communications, rail transit, home improvement and bathroom, aerospace and other fields.

Features introduction:

1. It has a detachable frame and a pre-tightened column structure, which has the characteristics of simple disassembly and installation, accurate positioning and coordination, and easy disassembly and transportation;

2. The frame of this equipment is analyzed by finite element computer, and each frame is annealing and aging treatment after welding to eliminate welding stress, effectively control the amount of deformation, and ensure the strength, rigidity and service life of the frame;

3. It adopts servo pump control system and logical proportional control, which has the characteristics of simple system, convenient operation, stable operation, energy saving and environmental protection;

4. It adopts Mitsubishi or Siemens PLC programmable controller, the man-machine interface adopts Chinese/English color touch screen, the electric control cabinet is strong/weak current separation, and the wiring is in accordance with CE requirements. It has the characteristics of being in line with international standards, strong recognition, convenient reading and writing, and simple operation;

Optional configuration:

Optional electric mold changing trolley, four-corner slow mold opening, external core pulling/ejection circuit, industrial oil cooler, mold temperature controller, fast mold clamping device, etc.

Photos taken in customer's factory

Production Process:

Certification:

1000T Hydraulic SMC Moulding Press Machine with CE Standard

1000T Hydraulic SMC Moulding Press Machine with CE Standard

Hydraulic SMC Moulding Press Machine is applied in compression moulding of comosites materials like SMC,BMC,FRP,GRP and so on.

Hydraulic Press for Composites SMC/BMC/GRP/FRP/GMT Molding

Hydraulic Press for Composites SMC/BMC/GRP/FRP/GMT Molding

SMC molding press is used for compression moulding of SMC BMC GMT and other composites material. 1. The frame is analyzed by finite element computer, and each frame is subjected to annealing and aging treatment after welding to eliminate welding stress, effectively control the amount of deformation, and ensure the strength, rigidity and service life of the frame; 2. It adopts servo pump control system and logic proportional control, which has the characteristics of simple system, convenient operation, stable operation, energy saving and environmental protection. 3. The integrated layout of the pipeline, compact and less leakage, and multiple safety protection circuits, with a sensitive response to meet the long-term safety production needs; 4. Adopt Mitsubishi or Siemens PLC programmable controller, human-machine interface adopts Chinese/English color touch screen, electric control cabinet strong/weak current separation, wiring are all in accordance with CE requirements. It has the characteristics of being in line with international standards, strong identification, easy to read and write, and simple to operate;

5000T Hydraulic Composites Forming Press

5000T Hydraulic Composites Forming Press

This equipment is specially used for compression molding of thermosetting/thermoplastic composite materials, including SMC, BMC, DMC, GMT, LFT-D, LFT-G and other materials; such materials are widely used in ships, automobiles, building materials, electric power Electrical appliances, electronic communications, rail transit, home improvement and bathroom, animal husbandry, aerospace and other fields.

2000T Hydraulic Press Machine for Forming SMC Door

2000T Hydraulic Press Machine for Forming SMC Door

SMC Door Forming Press is used for compression moulding of SMC Door Skin and other BMC FRP,GRP,GMT composites material.

Hydraulic Forming Press for SMC/GRP/FRP/GMT Molding

Hydraulic Forming Press for SMC/GRP/FRP/GMT Molding

SMC molding press is used for compression moulding of SMC BMC GMT and other composites material.

SMC Press with CE/NR Standard

SMC Press with CE/NR Standard

Hydraulic SMC press is used for compression moulding of SMC BMC GMT and other composites material.

1000Tons GMT/SMC Forming Hydraulic Press

1000Tons GMT/SMC Forming Hydraulic Press

GMT Forming Hydraulic Press is used for compression moulding of SMC BMC GMT and other composites material.If we have your basic requirements, like worktable size, stroke and max. daylight etc, we can provied you with accurate quotation.

2000tons Hydraulic Forming Press for New energy vehicle battery case

2000tons Hydraulic Forming Press for New energy vehicle battery case

This hydraulic press is used for New energy vehicle battery case.If we have your basic requirements, like worktable size, stroke and max. daylight etc, we can provied you with accurate quotation.

800tons SMC Hydraulic Press

800tons SMC Hydraulic Press

Hydraulic press is used for aluminum foil product forming.If we have your basic requirements, like worktable size, stroke and max. daylight etc, we can provied you with accurate quotation.

The professional team to service !